Grinding of Brake Pad for the Aerospace Industry

Examples of our Work

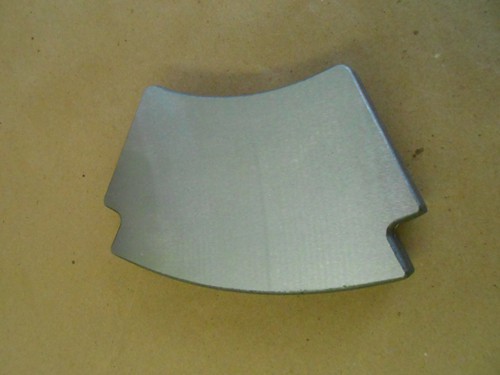

Precise Lapping & Grinding Corp. (PLG) was contracted by a customer in the aerospace industry to perform the precision grinding of this steel brake rotor segment. The required tolerances were extremely demanding, and PLG worked with the customer and a trusted abrasive manufacturer to develop the treatment process and the appropriate abrasive product to achieve specification

The rotor segment was composed of EMS 124 steel, measuring 5" in length by 3" in width by 0.700" in thickness.

Finishing requirements were met with our double disc grinding process, achieving parallelism to 0.0005". In process testing and inspections were carried out to ensure accuracy including height, flatness, and parallelism verifications. Turnaround time for this project is 5 to 7 days.

For more details about this double disc grinding project, or our flat surfacing capabilities please see the table below or contact us directly.

Highlight of Brake Pad Grinding Project |

|

| Product Description | Brake Rotor Segment |

| Capabilities Applied/Processes | Primary: Co-Engineering: Process Development Double Disc Grinding |

| Equipment Used to Manufacture Part | Double Disc Grinder |

| Overall, Part Dimensions | Length: 5.000"

Width: 3.000” Thickness: 0.700" |

| Tightest Tolerances | Parallel to 0.0005" |

| Material Used | EMS 124 Steel |

| In process testing/inspection performed | Height Checks, Flatness, Parallelism |

| Industry for Use | Aerospace |

| Delivery/Turnaround Time | 5 - 7 Business Days |

| Delivery Location | US |

| Standards Met | Customer Specifications, 2D CAD Drawing |

Examples of our Work

At Precise Lapping & Grinding Corp. (PLG), we provide precision grinding and lapping to customers in a wide range of industries. Here are just a few examples of the innovative solutions and value-added products and services that we deliver every day.

5120

Satisfied clients Precise Lapping & Grinding

15

Awards Winner Precise Lapping & Grinding

225

Combined years of experience